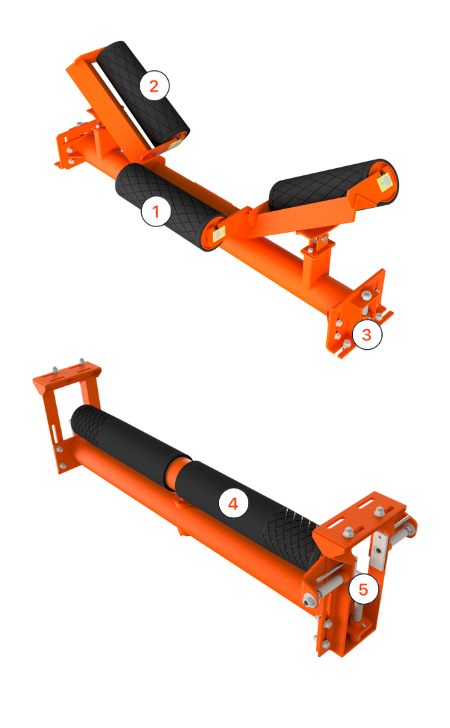

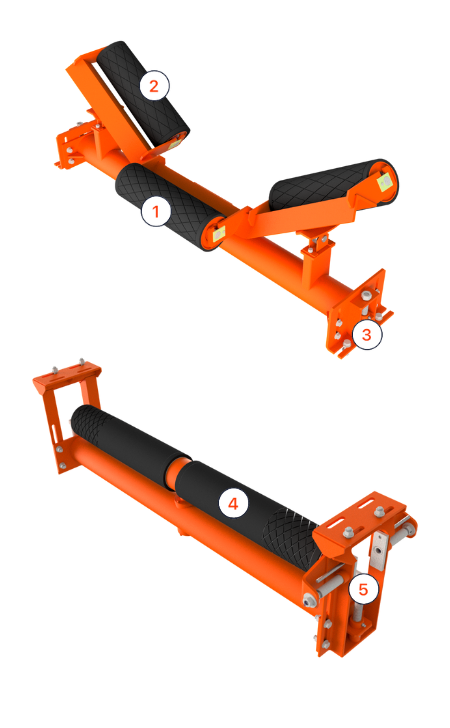

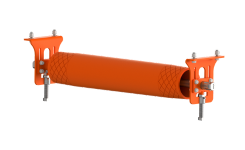

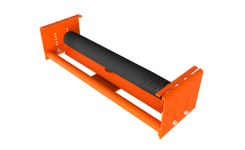

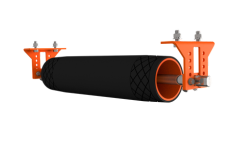

Manufactured without lateral training rolls to avoid scratches in the belt from wear and tear. The taper design of the rolls tips the belt towards the center. These consider reinforced and assisted pivot with lifelong sealed bearings.

Greater production efficiency: Properly aligned conveyor belts reduce spillage in the loading area.

Increased safety in the operation: By preventing spillage material, our transfer point products reduce the risk of workers slipping or falling during cleanup.

Greater service life of components: Because our products improve alignment, belts last longer without damaged edges, and there is a reduced demand on transmissions, pulleys and covers.

Lower maintenance costs: Keeping material on the belt means less spillage and fewer stoppages during production for cleaning.

All REVESOL rolls can be ordered with rubber or polyurethane lagging as required.