These are mechanical (screw-driven) devices to maintain the necessary tension on conveyor belts and feeders, ensuring that the belt has sufficient tension to generate the necessary friction between the conveyor belt and the drive and non-drive pulleys. It helps to offset belt length changes from elongation by limiting the belt deflection between the rolls to prevent material spillage.

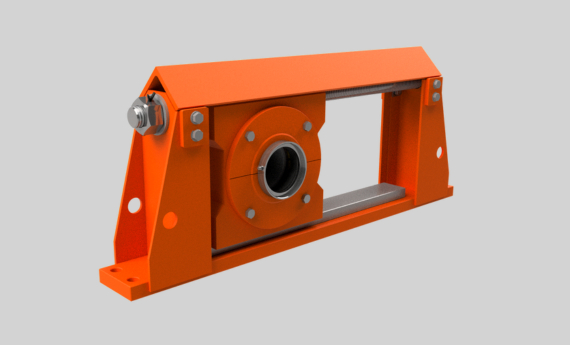

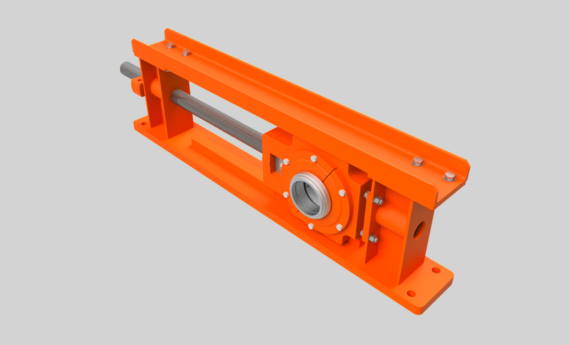

Heavy duty take-up frame top, with spherical roller bearings suitable for heavy duty environments. It is manufactured for shaft diameters from 100 mm to 200 mm and lengths from 305 mm to 1067 mm. The top angle protects the screw from contamination. It ensures precise belt tension.

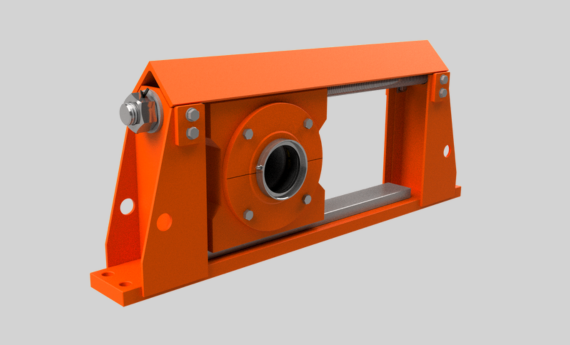

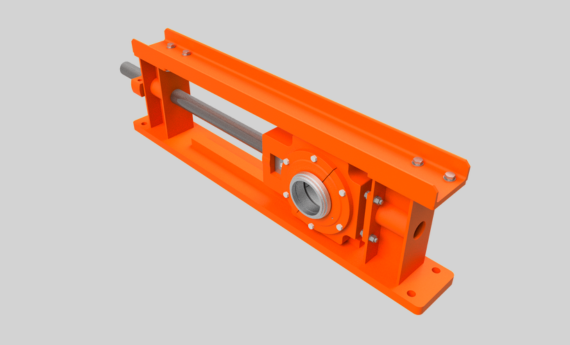

Medium duty take-up frame top, with spherical roller bearings suitable for heavy duty environments. It is manufactured for shaft diameters from 50 mm to 100 mm and lengths from 305 mm to 915 mm. The top angle protects the screw from contamination. It ensures precise belt tension.

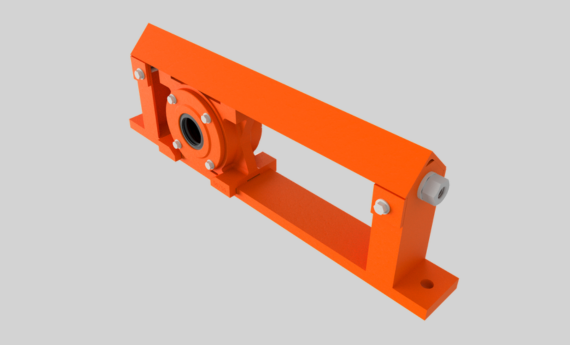

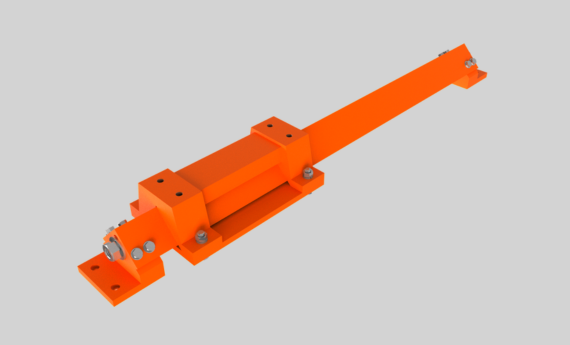

Heavy duty take-up frame center, with spherical roller bearings suitable for heavy duty environments. It is manufactured for shaft diameters from 50 mm to 200 mm and lengths from 305 mm to 1067 mm. It replaces pulley pillow blocks and ensures optimum tension. Hydraulic drive option.

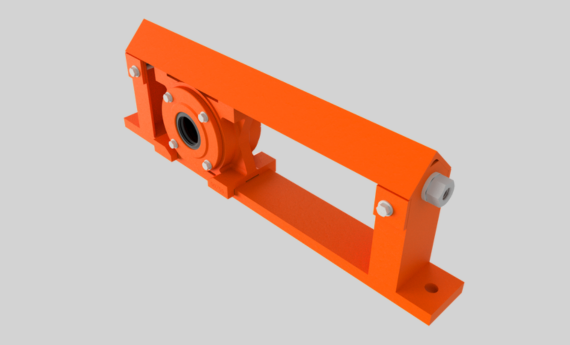

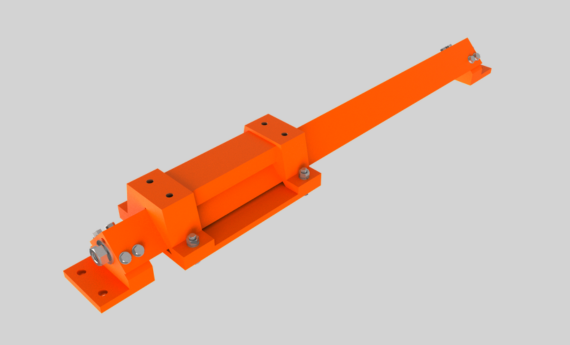

Heavy duty bottom take-up frame. It is manufactured in shaft diameters from 100 mm to 200 mm and lengths from 305 mm to 1067 mm. It can be adapted to 2- and 4-bolt pillow blocks, which can also be included in the take-up frame. It offers a smooth adjustment and hydraulic drive option.